Get Exclusive FIRST Access to:

New Product announcements

Ripper giveaways & promotions

Tips & tricks plus more...

Don’t Miss Out!

Become part of the RamFam and never miss out!

Error: Contact form not found.

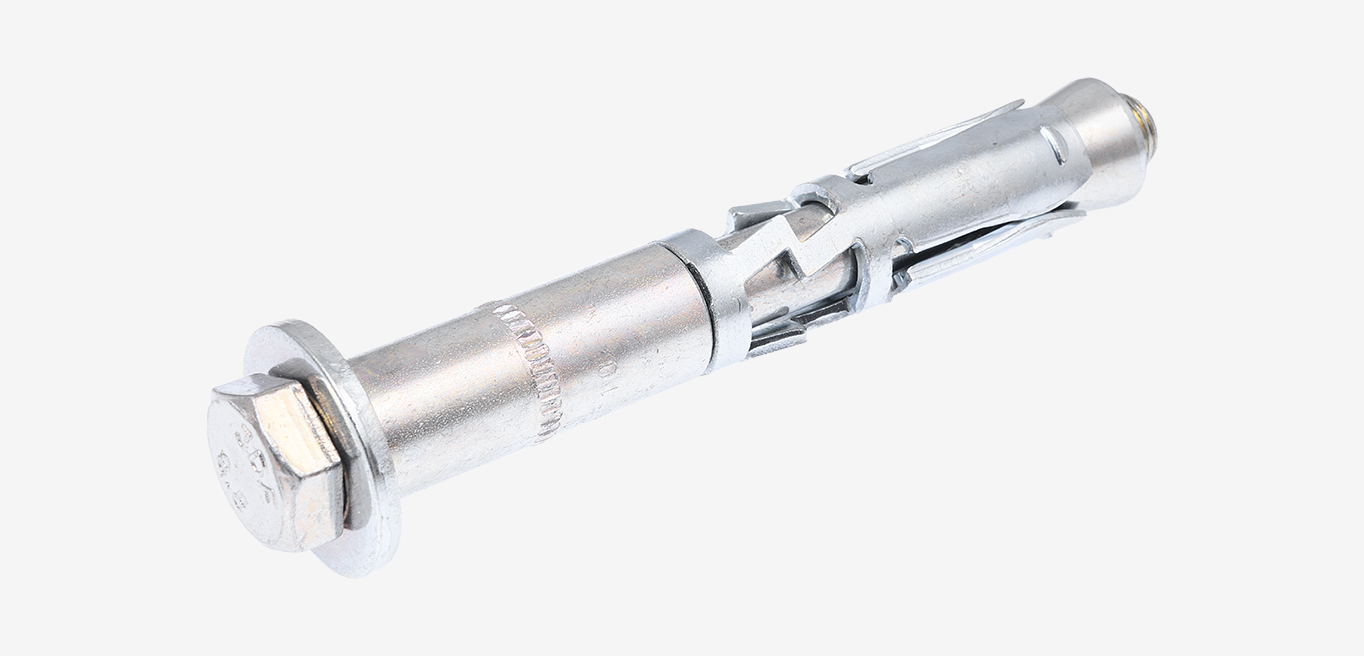

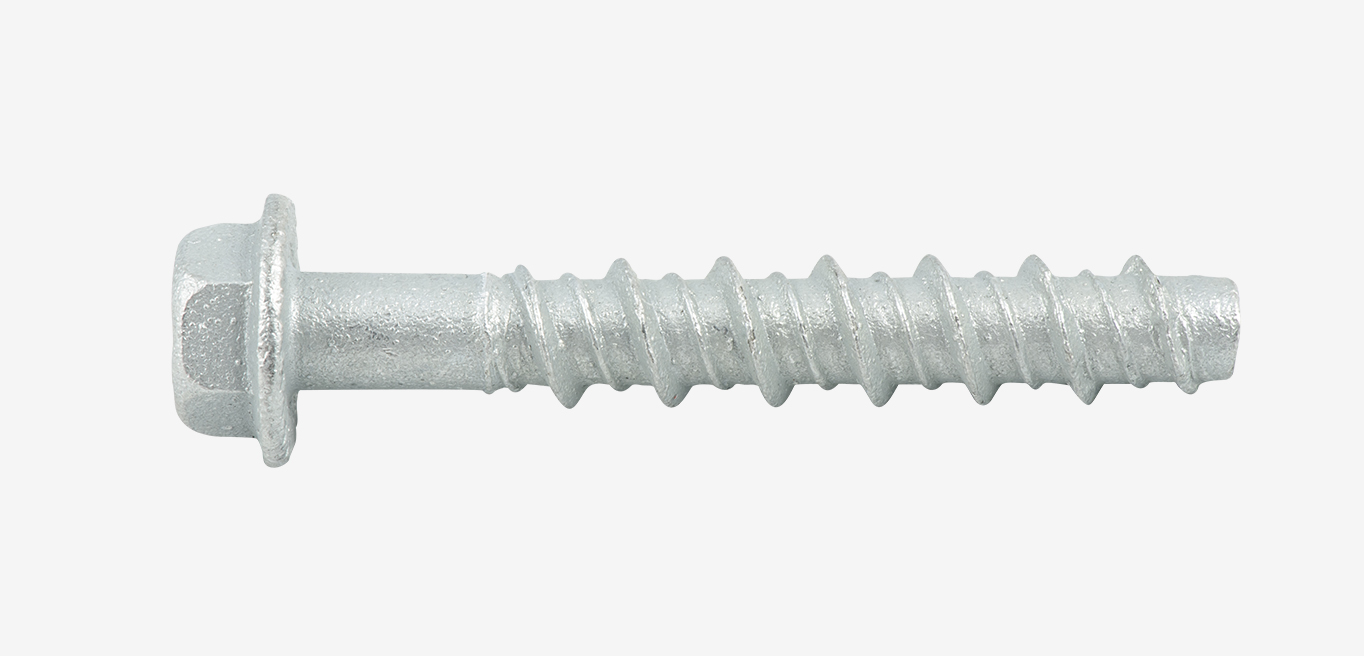

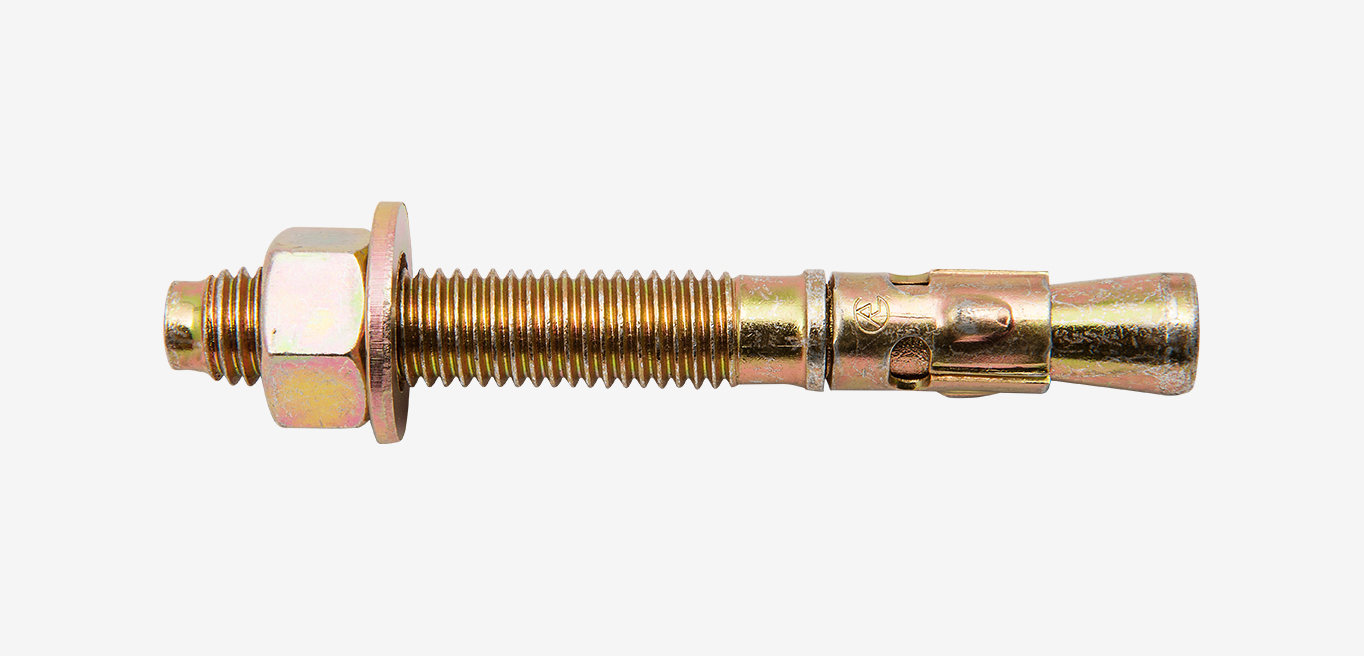

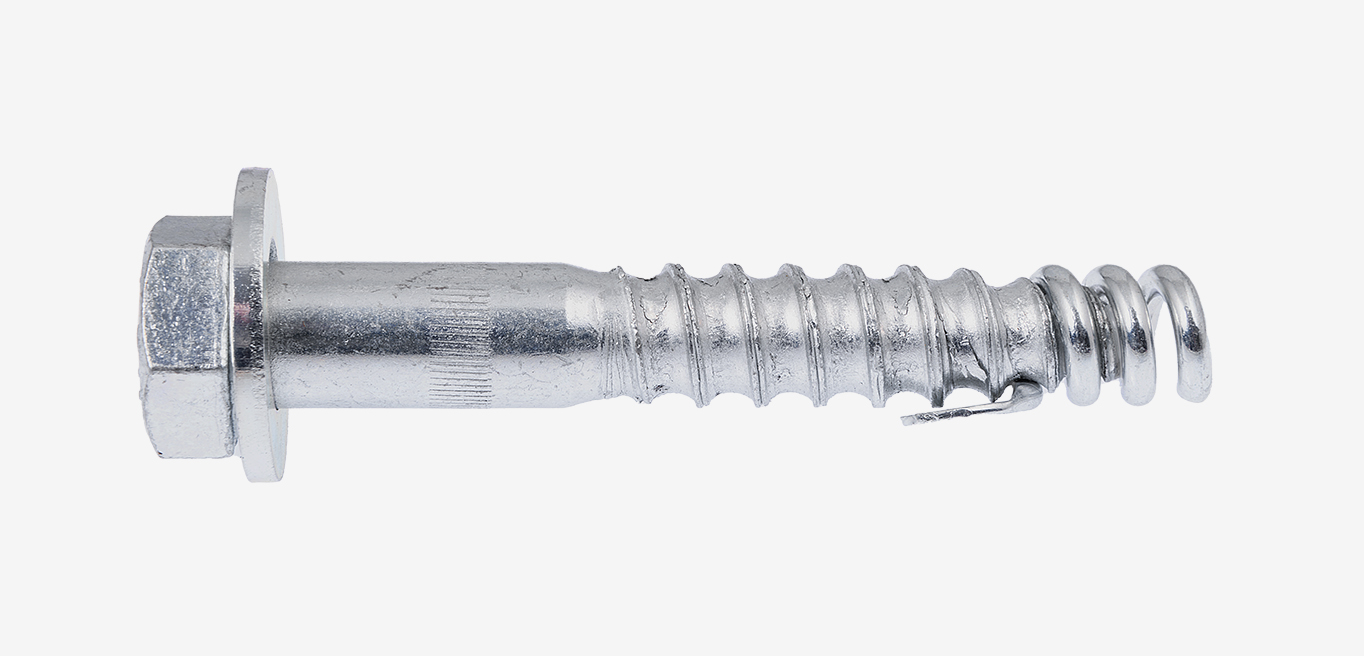

SpaTec™ Xtrem™

The SpaTec Xtrem Safety Anchor is a heavy duty, torque controlled expansion anchor, with an integrated pull-down section, designed for high performance in both static and dynamic load applications, in both cracked and non-cracked concrete and for seismic applications. Ideally suited for through fixing into concrete when security and reliability are paramount.

Thread Size

- M10

- M12

- M16

- M20

Anchor Length (mm)

- 105

- 120

- 145

- 170

Before visiting a Stockist or Service Centre, contact them to ensure product availability.

PART NUMBER:

Contact Details

-+PRODUCT INFORMATION

Click on the column headings to reorder the table.

| ITEM CODE | Thread Size | Anchor Length (mm) | Max. Fixture Thickness (mm) | Drilled Hole (mm) | Min. Hole Depth (mm) | Effective Length (mm) | Fixture Hole (mm) | Order Qty | ADD TO TOOLBOX |

|---|---|---|---|---|---|---|---|---|---|

| SP20170 | M20 | 170 | 25 | 28 | 165 | 150 | 32 | 5 | |

| SP16145 | M16 | 145 | 25 | 24 | 135 | 125 | 26 | 10 | |

| SP12120 | M12 | 120 | 25 | 18 | 115 | 105 | 20 | 25 | |

| SP12105 | M12 | 105 | 10 | 18 | 95 | 90 | 20 | 25 | |

| SP10105 | M10 | 105 | 20 | 15 | 95 | 90 | 17 | 25 |

STEEL ZINC PLATED

STAINLESS STEEL

GALVANISED STEEL

The selected variations added in the toolbox. Please view the items in the toolbox.

-+FEATURES & BENEFITS

- The combination of a high tensile class 8.8 bolt with an extra thick-walled spacer allows a smaller diameter bolt to be used for easier installation while still providing both excellent tensile and shear performance. The spacer also incorporates a visual maximum fixture thickness indicator for ease of use.

- The patented anti-rotation expansion sleeve is designed with sharp angled protrusions that grip the sides of the hole, preventing anchor rotation during installation.

-+APPLICATIONS & TRADES

| Anchoring structural steel column/beams | Steel Fabricator |

|---|---|

| Anchoring HVAC units | Plumbing Contractor, Electrical Contractor |

| Machinery hold down | Maintenance Filter |

| Anchoring crane rails | Construction Contractor |

| Anchoring elevator guide rails | Elevator Installer |

-+SPECIFICATIONS

| Material | Bolt Class 8.8 HighTensile Carbon Steel |

|---|---|

| Corrosion Protection | Zinc Plating |

| Head Styles | Hex Head (SP16145ESS-Hex Nut) |

| Fixing Method | Through Fixture |

| Setting Method | Torque Controlled |

| Anchoring Method | Expansion |

| Substrates | Concrete |